Practical solutions to improve the sustainable use of coolants in machining processes and reduce impact

There are multiple problems with soluble coolants

They contain mineral oil, an unsustainable resource, and have significant impact throughout the supply chain from supply of fluid to the recycling of swarf.

The traditional supply of soluble cutting fluids is a business model which is not aligned to sustainability. Suppliers rely on continually supplying barrels of 'oil' to meet sales targets.

The impact on swarf recycling and waste disposal is significant.

The United Kingdom Lubricants Association refer to 400,000 tonnes (~400 million litres) of ‘water / oil mix cutting fluids’ being disposed of annually in the UK.

We care that most of that volume will not have 'chemically failed'

And most importantly,

The Health & Safety Executive are concerned with the exposure risk to employees from working with coolants (aka cutting fluids / metalworking fluids / suds etc).

* continual risk to employee health.

* businesses have been prosecuted and fined significant sums for failing to provide

adequate control measures.

* the traditional approach to coolant management of occasioned pH, % and bacteria

checks, with retrospective reporting and delayed follow-up, does not control the risks.

* risks are greater in CNC and high performance machining applications.

* traditional coolant management does not determine exposure risks to employees.

In practise this means

Continual risk of exposure and delayed action to resolve health, environmental and productivity impacts.

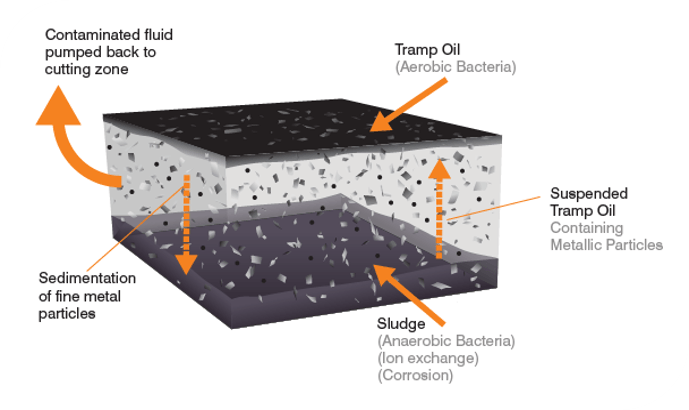

There is continual influx of contamination into the coolant conveyor tank and filtration system.

OEM conveyor tanks and filtration systems are inefficient at removing smaller particles of swarf, tramp oil and bacteria.

'Advanced' filtration systems, with above average performance, also retain harmful contamination.

Even when using additional control measures such as 'Tramp Oil' separators or 'Wet Vacs' to attempt to clean the coolant in situ harmful contamination remains.

And where a mist extractor is installed there is still risk of exposure when the machine doors are opened.

Soluble coolants are the most common used.

There is often a belief when a new coolant supplier is used a miracle product has been found. The smell goes, tool life increases and non-conformance reduces.

This is not down to 'fairy dust' in the formulation rather the machine has had a thorough clean out and with a new coolant added the bacterial resistance to the previous coolant has ended.

Regardless of the brand of coolant or claims of "excellent sump life" , "skin friendly formulation" or "increased tool life" once a coolant is in the sump and being used there is a constant ingress of contamination and it becomes hazardous.

Our approach works

"The non-conformance reduction attributed to the technology for the particular machining issues FMS was brought in to resolve has been nothing short of fantastic"

JH - Manufacturing Engineer

"Very attractive from a number of angles; reduced hazardous waste, improved component quality, reduced life cycle costs, less scrap"

NM - Global Head of Environment

"FMS have reduced our production costs, environmental impact and improved productivity"

SM - Toolroom Manager

References and blogs

Prosecutions happen

and are costly!

Say hello, we are here to help

If you would like to know more fill in a few details on the form and we aim to be in touch within the hour.

Alternatively, click the calendar to grab 30 minutes for an initial chat.

Fluid Maintenance Solutions LtdAdvanced

Manufacturing Park Technology CentreBrunel Way Rotherham South Yorkshire S60 5WG UK

We design, develop and manufacture in the UK technology to help improve health, productivity and environmental performance and reduce operations and maintenance costs.

Registered in England & Wales Co. No. 6679382

VAT Registration No. 940 2343 54 GB

Contact us for our policies on

Commercial Business Terms

Modern Slavery

Quality, Health, Safety, Environmental & Sustainability

Privacy, Terms & Conditions of Use

© Fluid Maintenance Solutions Ltd 2021